The toolpath requires a closed vector shape and will move the v-bit as deep as required to machine to the two vectors on either side of the bit.

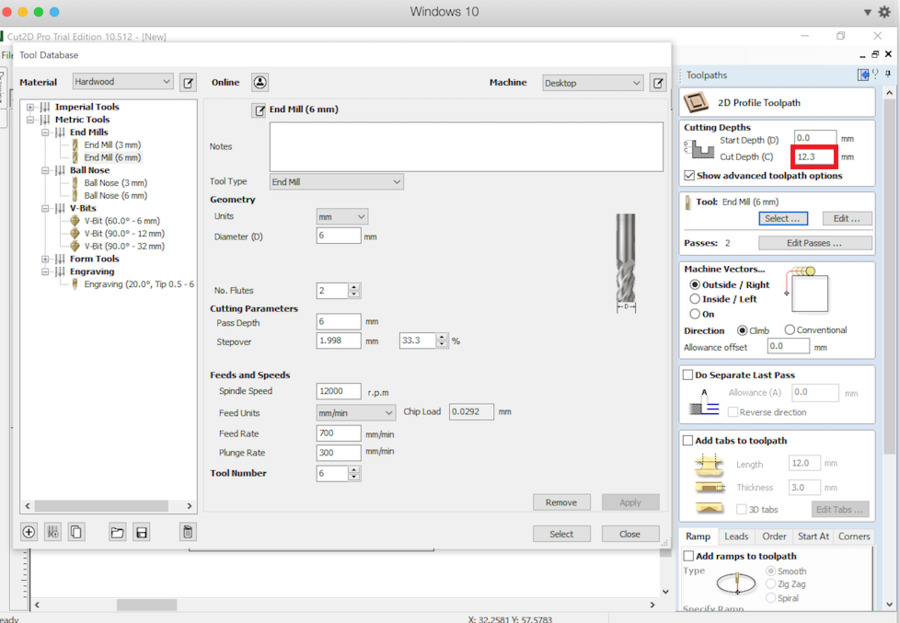

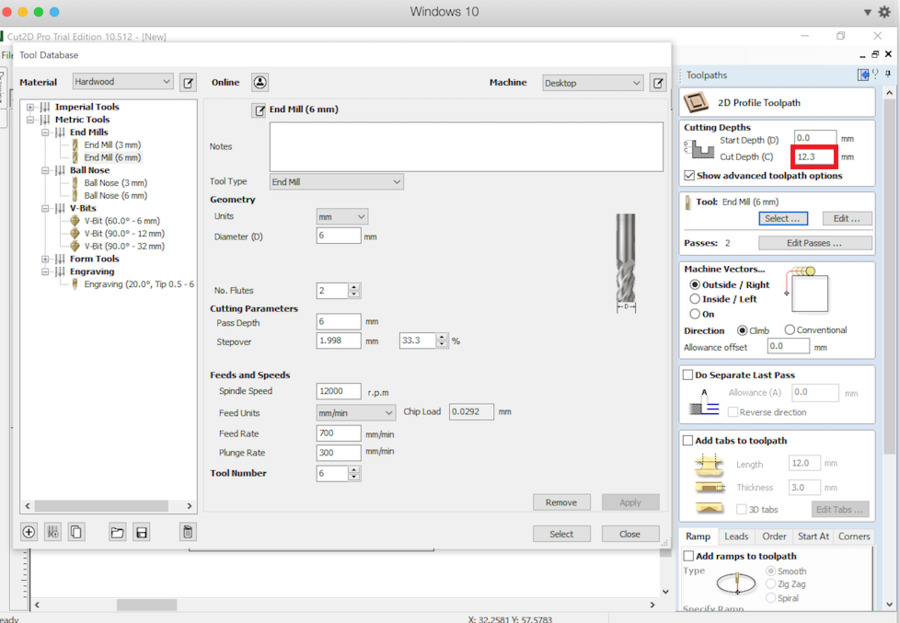

Edit Tab location and thickness on the profile Cut Out pass to ensure correct hold down of parts The V-carved Toolpath is unique because there is no way to set the Cut Depth. Please note: If set to zero then the finished box may be too tight to assemble, this is also CNC machine and tool tolerance accuracy dependant. Joint Width is the length of the dovetail required. Open the Toolpath Preview and check toolpaths are suitable and positioned correctly Define the width, the depth, and the height of the box required. The toolpaths are now automatically calculated. 125 inch deep just shy of.25 inch deep This makes no sense to me. Select Joint and lid type and press OK. 5 inch deep cut.but overall cut it quite a bit deeper than the. Select the endmill mill tool to be used. Please note: If set to zero then the finished box may be too tight to assemble, this is also CNC machine and tool tolerance accuracy dependant. Joint Width is the length of the dovetail required. Define the width, the depth, and the height of the box required. Select ‘Box Creator’ gadget from gadgets dropdown menu. Set the appropriate job size and material thickness. Please note: This is also very convenient option if the lid of the box is to be made from thicker material. This enables the user to maximise the size of the box required by placing the toolpaths on individual layers and so maximizing the machinable footprint of the CNC. With this in mind, if you are using a smaller CNC machine it is possible to select individual sides of the box by ticking the section required. Therefore, it is important to check the toolpath layout required will fit on the material available and the ‘machinable foot print’ of the CNC machine used for the project. it is not possible to move toolpaths to a new position once created. You may want to check out the Axiom forum for practical advise about how large a tool your machine can comfortably handle.Please note: The dovetail toolpaths created when using this gadget are locked to the layout position. If the machining times are too slow then I would suggest that you increase the cutting diameter incrementally until you get the production rate you desire without overloading your machine. end mill running a 100 inches per minute with the appropriate rpm and depth of cut for the material you are cutting can remove a lot of material in short order. I am guessing that you have the spindle option with an ER20 collet which gives you 1/2 in. If you wish to improve production times I would first recommend experimenting with your feed rates with tools no larger in diameter than your largest collet for pocket and profile work. With that said, 1 1/2 inch diameter tools can put a lot of stress on machines that size. #Vectric cut2d pass depth trial

A Fully Functional Trial Version is available to download from - www.

Vectric Photo VCarve - Vectric Cut 2D Desktop - DeskProto 7 Multi Axis Hobby - Vectric Cut2D Pro. Better understand how v-carving works with this. I do not own an Axiom machine but I certainly believe that for the money they are fairly rigid. In most toolpaths you can set a Pass Depth for the selected bit.

Almost any manufacturer of end mills has a high speed steel line. Probably great for surfacing spoil board or as a finish tool to clean up a largely finished pocket. The cutting recommendations for that, and the rest of the tools in that family, are that they are designed for very shallow broad cuts. Otherwise we would need more information of what you are trying to do. It should be enough to shave off any fuzzies. 5 DOC, rerun that toolpath with a start depth of. And what I mean by that is, after the toolpath is done with the. Again, you could try to reduce the pass depth, or run a finish carve over the last the carve. Softer wood like pine will easily create fuzzies and burrs. Another factor is the type of wood you are carving/cutting. That Amanda tool bit is mainly for surfacing, which I would only use very small amounts of DOC. 480 and then either create a finish toolpath with a start depth. Another technique I've used is to set the DOC to something like. You could try reducing the pass depth and see if that helps. Without knowing what each tool settings are, I might assume that your pass depth and/or your stepover might be too much for each of the endmill tools you are trying.

0 kommentar(er)

0 kommentar(er)